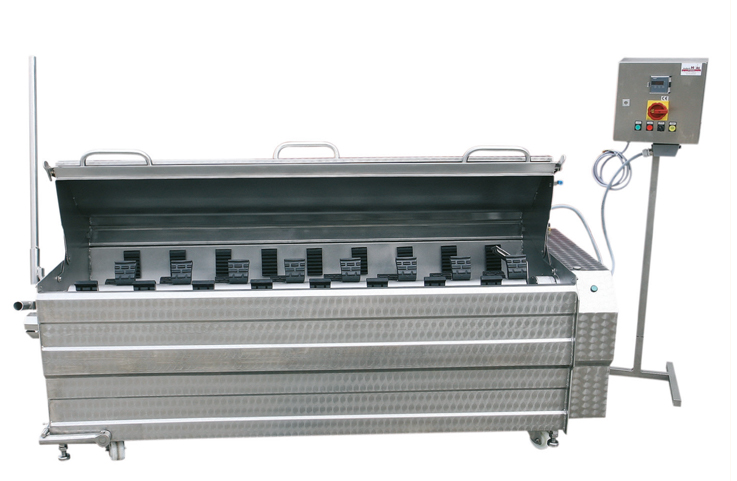

Equipment

- 2 roller systems for thorough dehairing

- Head scrubbing holder for difficult-to-reach head area

- Mobile on 4 castors

- New-design reinforced gearing

- Special scraper paddles (on rear panel as well)

- Electric heater in oil bath

- Integrated control and operating unit in machine housing

- Swing-out rollers for cleaning the machine

Options

- Galvanised or stainless steel throughout

- Choice of internal lengths

- Bristle screw

- Integrated bristle collector for catching the bristles in the machine

- Compressed-air ejector

- Compressed-air lid (choice of lid types)

- Electric wall control unit in stainless steel casing

Version with integrated bristle screw

It discards bristles and dirt out of the machine throughout the scalding/dehairing process.

The resulting consistently high water quality ensures

- consistently good scalding/dehairing

- higher slaughter capacity per water filling

An additional water supply is possible.

Processing sequence in automatic scalding and dehairing machine

- Fill machine with water up to lower shaft

- Heat up water using thermostatic control

- Place animal for slaughter into machine

- Start scalding process (stops automatically after approx. 3 minutes)

- Ejection of dehaired animal for slaughter automatically using ejector lever (pneumatic cylinder) or by hand

Choice of lid types

- Sliding/folding lid

- Folding lid (complete lid)

- Custom-height lid (for larger pigs)

- Automatically operated lid opener

Automatically operated lid opener

- After inserting the pigs, the lid closes at the touch of a button and the scalding and dehairing process starts.

- Machine stops automatically after the set time has elapsed (approx. 3 minutes) and the lid opens

- The pig is ejected by pressing a button

Download/Video

Technical specifications

| Dimensions | |

|---|---|

| Internal length | 1.900 mm |

| External | 2.500 x 1.000 mm |

| Internal length | 2.200 |

| External | 2.500 x 1.000 mm |

| Internal length | 2.500 mm |

| External | 2.800 x 1.000 mm |

| Total weight | Approx. 570 kg |

| Electric heater capacity | Choice of 13.5 to 24 KW |

| optional | Steam, gas or oil heating |

| Drive unit rating | 2.2 KW 380/400V 50 Hz 3-phase (custom voltages also available) |

| Water capacity | Approx. 200 litres |

| Scalding and dehairing time | Approx. 3 minutes |

| Max. pig weight | Approx. 350 KG |

| Processing capacity | 15 – 20 pigs/hour |